*Technical data is based on lab studies conducted by Dow. Results may vary depending on test conditions.

Airbag Safety

Airbag covers & airbag chute

The development of autonomous driving technology has further increased the requirements for passive protection systems. Increase of the quantity of airbags and reduction of collateral damage upon airbag inflation are now common demands from the industry.

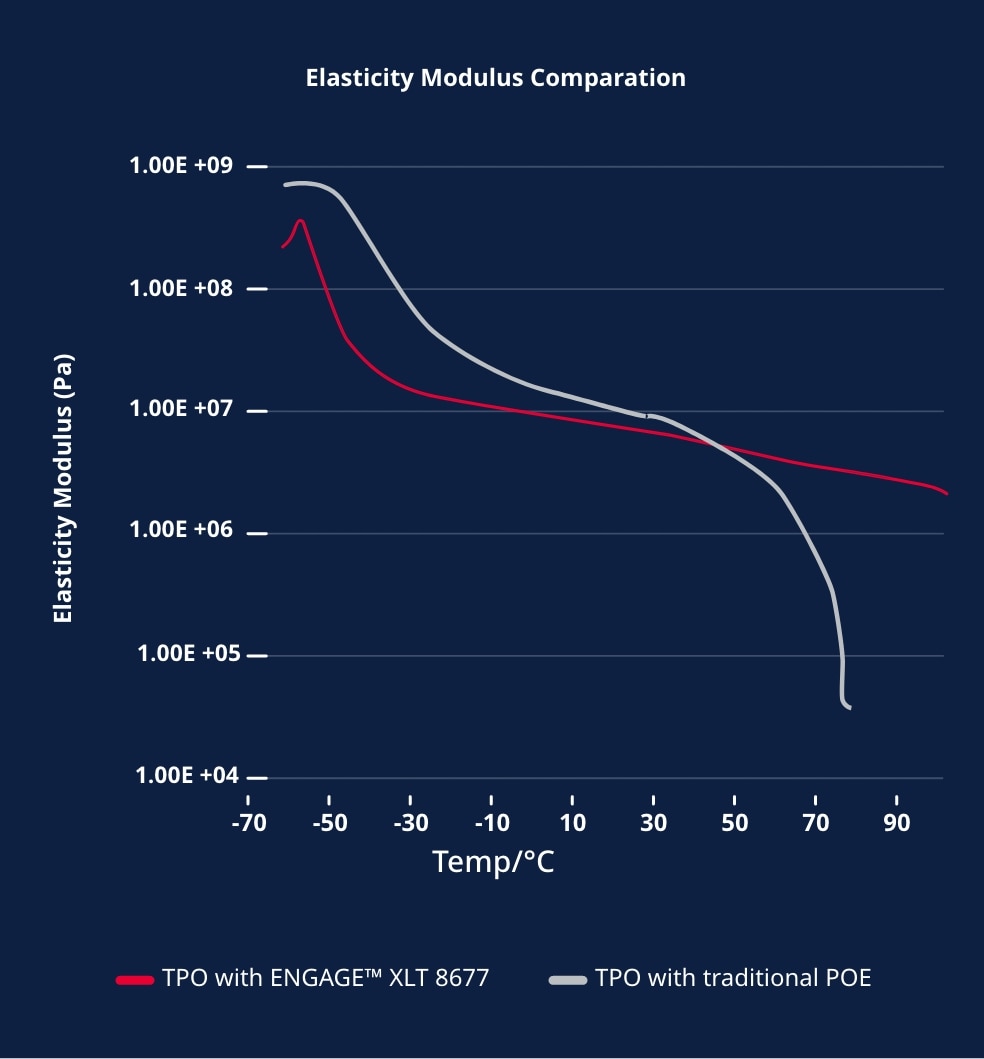

ENGAGE™ XLT 8677 POE

can ensure excellent ductility even under

low temperature, while INTUNE™ OBC has excellent

compatibility to increase the

stability of TPO’s performance.

*Technical data is based on lab studies conducted by Dow. Results may vary depending on test conditions.

Airbag coating

Today, the number of airbags equipped in each car is increasing. Lighter weight, reduced stiffness and enhanced packaging options – along with higher performance and lower costs – are typical design requirements for advanced airbag systems.

SILASTIC™ LCF 3600LV Liquid Silicone

Rubber features low emissions, high durability and excellent adhesion

to a variety of fabrics, meeting the needs above.

Pedestrian Safety

Bumper

The design and choice of materials used in bumpers must prioritise pedestrian safety. When used in bumpers, TPO has to retain appropriate hardness as well as toughness under a wide range of temperatures.

ENGAGE™ XLT 8677 POE

provides superior balance to control TPO modulus with robust temperature resistance, ensuring bumpers function as intended.

*Technical data is based on lab studies conducted by Dow. Results may vary depending on test conditions.

Adaptive Driving Beam (ADB) Systems

ADB systems help drivers keep their high beams on at all times and intelligently adjusts light intensity according to traffic and environmental conditions. However, ADB systems need specific high-performance silicones to perform well.

SILASTIC™ MS-5002 Moldable Silicone offers excellent

optical performance, high reliability

in extreme weather conditions, and flexible application across many kinds of designs – helping manufacturers make better ADB systems that keep drivers and pedestrians safe.

Battery Safety

Cooling tube systems

The skyrocketing use of batteries in hybrid and electric cars brings more challenges to cooling tube system design. Working temperatures must now be maintained at low levels and at longer operation times.

Dow provides multiple material technologies – from

EPDM to POE to

functional polyolefins

– to address optimization needs such as

lightweighting, recyclability, flexibility, temperature resistance. Our expertise in material technologies can help you accelerate the development of optimized electric vehicle (EV) battery systems.

Assembly Adhesive Solutions

To create high-performance EV battery packs that meet typical design requirements, manufacturers must use adhesive solutions with tailored mechanical properties that enable process flexibility during production.

VORATRON™ EVs battery pack

assembly adhesives can provide a wide range of different

thermal conductivities and

mechanical properties, enabling manufacturing automation.

Driver Safety

Driver Safety