Dow and Carbice

Combining the power of silicones and carbon nanotube technology for unmatched thermal management solutions

Pioneering nanotube thermal management and interfaces

We are combining decades of Dow silicone expertise with patented carbon nanotube (CNT) technology from Carbice to provide innovative thermal management solutions providing enhanced conductivity, reliability and tunability. This partnership unites Dow and Carbice’s capabilities to simplify thermal interface management (TIM) selection, offering predictable and affordable consumer, industrial and manufacturing solutions.

We offer custom solutions and early design engagement, optimizing performance and cost-efficiency for each specific thermal management application. This cutting-edge technology is available for a wide range of industries, including mobility, industrial and consumer electronics, and semiconductors.

Unique solutions to solve thermal management challenges

By integrating silicone with CNTs, we can design durable thermal management solutions with excellent interface contact, lowering stress transfer for reliable performance in any environment.

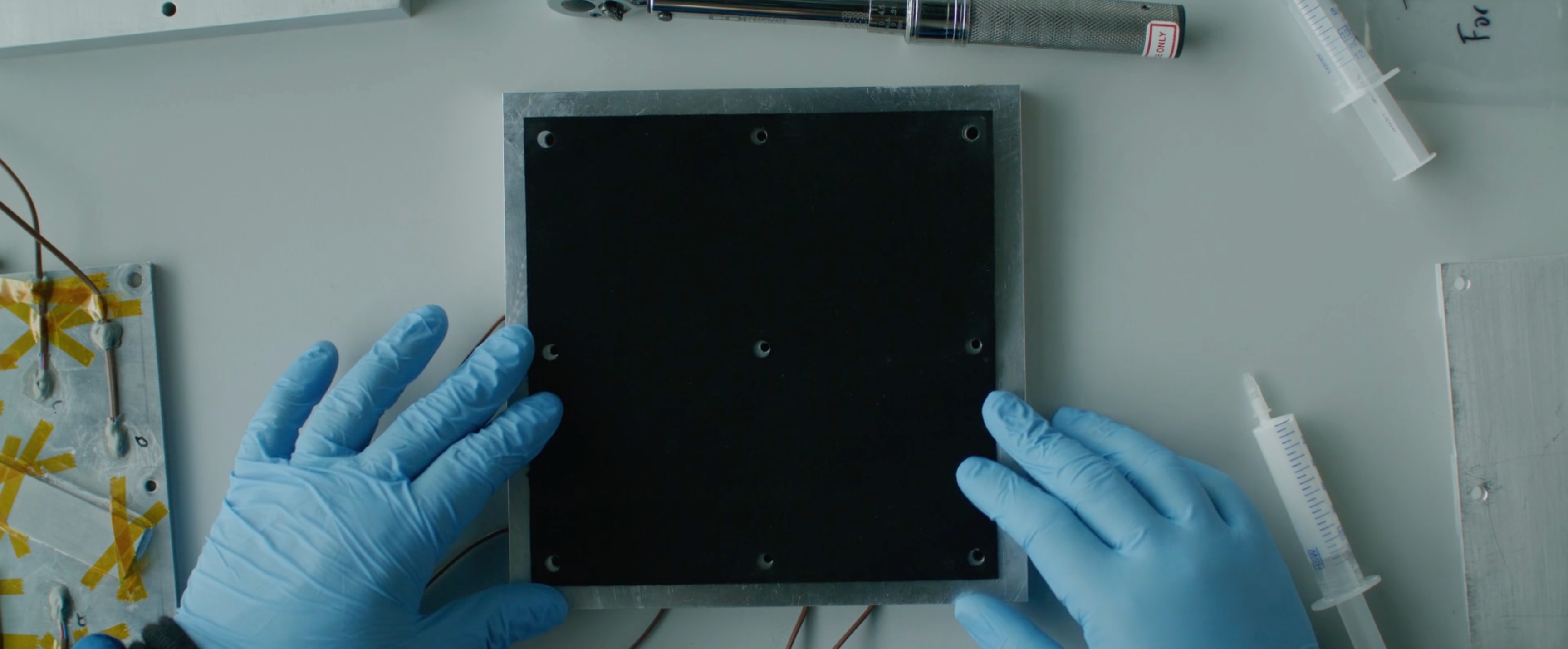

Carbice CNTs are durable, reworkable thermal pads but can lose effectiveness on uneven surfaces. Dow liquid silicones can be dispensed exactly where needed but lack the strength of a physical pad. Together, these materials complement each other and enable superior performance, customization and thinner bondlines.

Expanding Dow Carbice joint portfolio

Our ongoing joint research and development supports continuous delivery of cutting-edge, next-generation thermal management solutions. We are excited to launch our solution portfolio with the following two products, which are available for sampling and will be fully commercialized in 2025.

Carbice® SW-90 with Silicone Wax

Carbice ® SW-90 with Silicone Wax helps with wettability of the pad so that the rigid pad can have effective contact for heat transfer on a non-regular surface.

Carbice® SA-90 with Silicone Adhesive

Carbice ® SA-90 with Silicone Adhesive offers a unique assembly solution without mechanical fastening. The pad can be picked and placed using adhesive for easy assembly.

Differentiated thermal interface materials

Partner with Dow and Carbice to unlock a distinctive blend of technology and industry expertise that you can rely on.

Achieve superior thermal management with exceptional wetting capabilities, ease of assembly and reworkability across a wide range of applications.

Surface wetting from Dow and aligned CNTs from Carbice create excellent interface contact that lowers stress transfer for more reliable performance, in any environment.

Benefit from access to world-class testing capabilities to validate performance, reduced thermal solutions manufacturing complexities and shorter lead times.

Collaborate during the design phase to leverage our unique modeling capabilities, enable customization and optimize TIM solutions tailored for your specific application.