What is DOW™ DA61 HL Enhanced Polyolefin Resin?

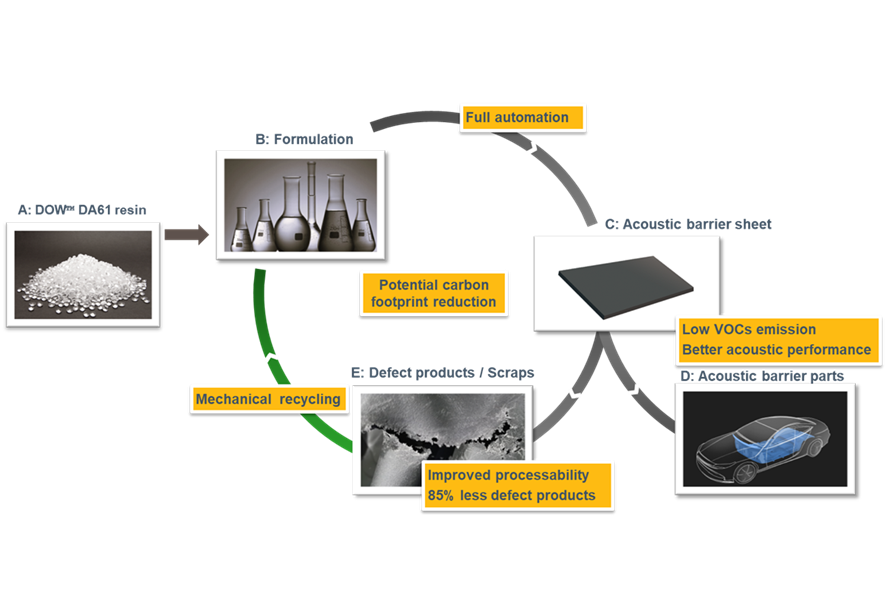

A resin used in extruded acoustic barrier compounds for flooring, wheel well, and dash mat applications, providing enhanced acoustic comfort. Its unique polymer architecture allows for high levels of organic filler while maintaining mechanical properties. The non-polar polymer structure results in compounds with low volatile organic content (VOC) emissions, exceptional durability, and the ability to recycle industrial scrap.

Uses

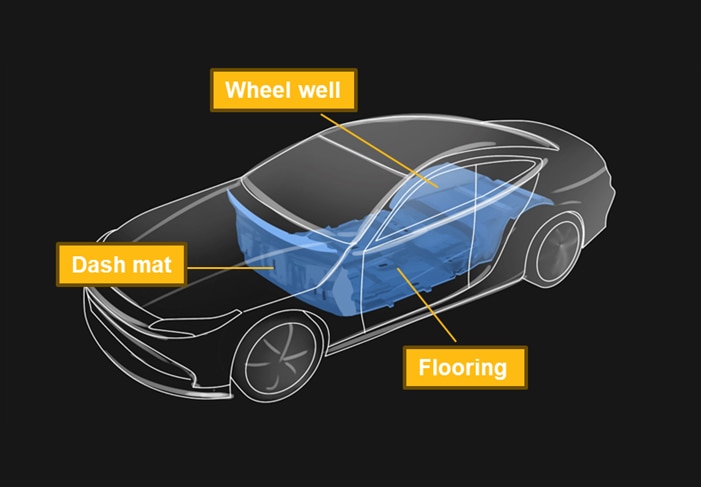

- Acoustic barrier application: Dash mat/firewall, flooring, wheel well, and door applications

Benefits

- High filler level loading (~75wt% or greater) while maintaining excellent tensile and tear properties

- Exhibits low crystallinity, providing flexibility with low oil content

- Completely free of phthalates and vinyl acetate, resulting in low VOC and odor emissions

- Offers excellent durability and ductility at temperatures as low as -30°C

- Allows for the potential mechanical recycling of post-industrial scrap

- Demonstrates excellent rheology for web stability during extrusion

- Provides outstanding melt elongation, resisting thinning or tearing during thermoforming

- Potential for enhanced automation due to the reduced number of components needed

DOW™ DA61 HL Enhanced Polyolefin Resin

Solutions enable safer, more comfortable, and more sustainable mobility acoustic solutions

Interested in reviewing additional technical information?